Almost four years ago I bought a 60cm wide very basic vinyl cutter and a stand alone PC with some basic software and a box of mixed budget vinyl to make my own stickers and graphics for a race car that a friend and I were building.

The machine, computer and material found a place in my spare bedroom at home and I started to experiment.

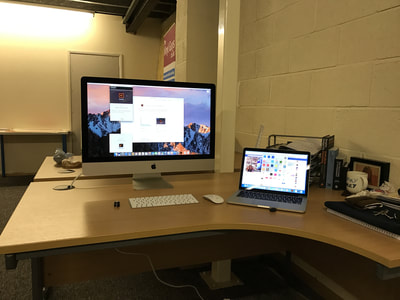

Today, with the help of a trainee installer I run a busy and fast growing print business from a 950sq foot installation centre. 18 months ago I bought a state of the art Roland print and cut system, laminator and now use top of the range Macs packed with the latest design software & vehicle proofing packages to cater for the design, production & finishing of full & partial wraps, vehicle graphics, retail signage, banners, labels and pretty much anything else a customer could possibly want to promote their business. I had managed to do all of this in my spare time along side a full time career too!

The machine, computer and material found a place in my spare bedroom at home and I started to experiment.

Today, with the help of a trainee installer I run a busy and fast growing print business from a 950sq foot installation centre. 18 months ago I bought a state of the art Roland print and cut system, laminator and now use top of the range Macs packed with the latest design software & vehicle proofing packages to cater for the design, production & finishing of full & partial wraps, vehicle graphics, retail signage, banners, labels and pretty much anything else a customer could possibly want to promote their business. I had managed to do all of this in my spare time along side a full time career too!

It's been an interesting journey so far.

I've been on a number of hands on training courses, become qualified in wrapping and vinyl application skills, watched countless YouTube videos, experimented on my own vehicles, done work for free to hone my skills, met with reps to discuss material properties and compared different manufacturers materials. I've also been to trade shows, demo days and generally tried to speak to as many experts and business owners in the sector as possible to continually improve on what I can offer.

I spend hours every day watching social media to see what other people are doing, engaging with clients and potential customers and generally promoting the amazing work I've created. I've squeezed the most out of every single waking moment I had, every day to create and grow the business that I so proudly own and run today and I've done this along side a full time career (in a totally different sector to anything even closely related to print or signage).

A huge proportion of the amazing advice, tips and techniques that I've been lucky enough to be given along the way have been from people willing to talk to new comers to the industry, YouTubers trying to help people with advice & demos and from already successful business men and women from a range of sectors, all of whom have given their time and advice for FREE and I would like to start to do the same.

I've been on a number of hands on training courses, become qualified in wrapping and vinyl application skills, watched countless YouTube videos, experimented on my own vehicles, done work for free to hone my skills, met with reps to discuss material properties and compared different manufacturers materials. I've also been to trade shows, demo days and generally tried to speak to as many experts and business owners in the sector as possible to continually improve on what I can offer.

I spend hours every day watching social media to see what other people are doing, engaging with clients and potential customers and generally promoting the amazing work I've created. I've squeezed the most out of every single waking moment I had, every day to create and grow the business that I so proudly own and run today and I've done this along side a full time career (in a totally different sector to anything even closely related to print or signage).

A huge proportion of the amazing advice, tips and techniques that I've been lucky enough to be given along the way have been from people willing to talk to new comers to the industry, YouTubers trying to help people with advice & demos and from already successful business men and women from a range of sectors, all of whom have given their time and advice for FREE and I would like to start to do the same.

There are an enormous number of home print-shops popping up all over the UK designing and creating a range of amazing products from labels and stickers to tee shirts, vehicle graphics and wall art.

As print technology becomes more advanced yet easier to use as well as increasingly affordable the path to the freedom of making a living from your spare room is easier than ever, but speaking regularly to a number of new "bedroom business" owners one ingredient seems to be regularly forgotten or under estimated.....how much HARD WORK it is!

I've captured thousands of images of my business set up from day one, jobs I've done, notes on materials, pricing, things that have gone wrong, suppliers and business owners who've given great advice and a whole host of other notes from the journey.

I'd love to share these with anyone who's interested in whatever format helps the most be it video, in person, email or any combination of media to help new business owners grow their companies and meet their personal goals and targets.

There is enough work in the sector for everyone and no huge secrets to uncover, I just want to share what's worked for me and how I've grown my business into what it is today and repay the kindness that was afforded to me at the start of my journey.

The way I've started and grown my business will be different to some of you as I've had to do it in my spare time and sometimes sacrificed sleep and leisure time to get things done.

I have a young family, my wife and I have an 8 year old daughter and an 18 month old puppy so I've also worked hard to keep the balance between my work and family time (which I've got better at over the last 12 months)

As print technology becomes more advanced yet easier to use as well as increasingly affordable the path to the freedom of making a living from your spare room is easier than ever, but speaking regularly to a number of new "bedroom business" owners one ingredient seems to be regularly forgotten or under estimated.....how much HARD WORK it is!

I've captured thousands of images of my business set up from day one, jobs I've done, notes on materials, pricing, things that have gone wrong, suppliers and business owners who've given great advice and a whole host of other notes from the journey.

I'd love to share these with anyone who's interested in whatever format helps the most be it video, in person, email or any combination of media to help new business owners grow their companies and meet their personal goals and targets.

There is enough work in the sector for everyone and no huge secrets to uncover, I just want to share what's worked for me and how I've grown my business into what it is today and repay the kindness that was afforded to me at the start of my journey.

The way I've started and grown my business will be different to some of you as I've had to do it in my spare time and sometimes sacrificed sleep and leisure time to get things done.

I have a young family, my wife and I have an 8 year old daughter and an 18 month old puppy so I've also worked hard to keep the balance between my work and family time (which I've got better at over the last 12 months)

In my full time job I work shifts so often have days free when I'm off, my daughter is at school and my wife is at work so I find plenty of days to run the business as a "9-5" but being used to working night shifts also means that on the occasions when it's needed I don't have a problem running overnight print runs and offering over night vehicle installations.

This serves my clients well, works for me and also means my customers benefit from reduced vehicle down time and a quicker turnaround. For overnight and priority work I also charge a premium so the business benefits well from these jobs too.

The main theory that's kept me going is "short term pain long term gain" by which I guess I'm saying, yeah it's hard work at the moment and I'm often tired and working very long days, (sometimes 16-20 hours) but it will be worth it in the future when I plan to make the business my full time career.

My long term plan was always to build the business, invest everything that it generated back into equipment, premises and training so that it owed nothing and when I felt ready and able to make the move, take the plunge and leave my career, the business would already be running successfully and generating a decent profit.

As I said earlier, the path I'm taking won't be for everyone. If I hated my day job I'd have left by now and already be running my business full time. Similarly, if I didn't have a young family maybe I'd have taken more of a risk and left already, but this is the way I've done it and it's working for me in my current situation.

That said, a lot of what I want to share is relevant to a whole range of business types in different sectors and different stages of growth so take from my journey what you want, what you can use and if there is anything you'd like to know in more detail please feel free to contact me and ask. That's the first thing to take form this right there, don't be afraid to ask!

The Start

I took a drive up to Manchester to collect my first machine. I had never used one, seen one working or even thought about which one to buy before but I had recently paid what I considered to be too much for a set of small stickers for our race car and I thought this was a much more cost effective plan.

I'd found the package deal for this one on eBay and the seller had great feedback and their business was established and they'd given some advice to me already through a few messages so they seemed like the perfect choice, after all I'd never intended this machine to be for anything other than my own light use.

An hour and a half drive and I was at the shop. For my £700 I was getting a brand new 600mm Liyu vinyl cutter with a used desktop PC pre loaded with some sign cut software and the drivers for the cutter so it was a "plug and play" solution.

It was great, I was so excited. I saw the machine working, had about an hours tutorial and selected a few boxes of vinyl to experiment with along with a few essential tools like squeegees, weeding tools, magnets, cutting mat and a metal rule and I was done.

I loaded up the car and drove home. Everything was set up relatively trouble free. I recreated what I'd been shown in the shop to show my wife exactly what I'd spent my money on and she was semi-impressed although like with the race car, I think she was humouring me.

I'd found the package deal for this one on eBay and the seller had great feedback and their business was established and they'd given some advice to me already through a few messages so they seemed like the perfect choice, after all I'd never intended this machine to be for anything other than my own light use.

An hour and a half drive and I was at the shop. For my £700 I was getting a brand new 600mm Liyu vinyl cutter with a used desktop PC pre loaded with some sign cut software and the drivers for the cutter so it was a "plug and play" solution.

It was great, I was so excited. I saw the machine working, had about an hours tutorial and selected a few boxes of vinyl to experiment with along with a few essential tools like squeegees, weeding tools, magnets, cutting mat and a metal rule and I was done.

I loaded up the car and drove home. Everything was set up relatively trouble free. I recreated what I'd been shown in the shop to show my wife exactly what I'd spent my money on and she was semi-impressed although like with the race car, I think she was humouring me.

I set about practicing, learning to use the software through YouTube demos as well as my own trial and error. I had to try and get my head around the limits of the cutter and understand what I could and couldn't do. This machine wasn't a printer, it would cut out shapes, letters and designs from vector files in pre coloured self adhesive vinyls, of which there was an almost never ending range from £1 per metre all the way up to over £80 per metre for wrap vinyl with air release adhesive linings and other features I didn't really then see the benefits of.

I had worked out how to turn simple logos, basic images, shapes and text into vector (.eps) files and also got to grips with creating these files from scratch. Sometimes I'd have the odd wobbly line from transforming the PDF or jpeg into vector but I soon worked out how to smooth curves and replace imperfect lines with the hundreds of design tools the software offered.

I had also made use of font matching websites to replace text parts of logos, as these would very rarely transform perfectly and imperfect cut lines would always bother me and result in a far from perfect end result. There is also a really useful website that has a huge range of the most popular and common brands logos available for free in a range of formats including vector so I made regular use of this too.

I had worked out how to turn simple logos, basic images, shapes and text into vector (.eps) files and also got to grips with creating these files from scratch. Sometimes I'd have the odd wobbly line from transforming the PDF or jpeg into vector but I soon worked out how to smooth curves and replace imperfect lines with the hundreds of design tools the software offered.

I had also made use of font matching websites to replace text parts of logos, as these would very rarely transform perfectly and imperfect cut lines would always bother me and result in a far from perfect end result. There is also a really useful website that has a huge range of the most popular and common brands logos available for free in a range of formats including vector so I made regular use of this too.

|

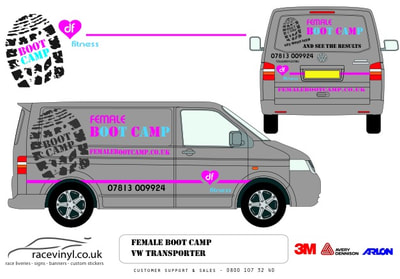

After a while I had proudly decorated the race car with a number of custom logos and graphics as well as the odd small sponsor logo.

I started to have less of a use for the machine and it felt like I had £700 sat in the corner of the spare room doing nothing. So one evening I started to look around on eBay to see what people were selling basic cut vinyl vehicle graphics and lettering for. I was surprised at how many there were being sold.You could pretty much have lettering for both sides and the back of a standard transit van for £30 and a few pounds postage. If I was using the most basic cheap vinyl in a single colour I could probably do that from about £5-£6 worth of vinyl so after fees, postage and tax there was a half decent mark up. I tested the water by creating an advert for van lettering in single and mixed colours. I pitched at a similar price and bought a range of colours in basic vinyl. |

After a couple of weeks I had sold a few. There was more time than I'd thought involved in set up, cutting, weeding, applying the application tape and then packaging them up and I'd also under estimated my postage costs by about £3 per item as well as the cost of my postage tubes, so in reality I'd probably about broken even on my first few sales.

Being passionate about motorsport and knowing how much of a dent in a budget that a race livery can have, I had decided that the main customer base I was looking for was motorsport.

I named the company Racevinyl. Pretty simple really. I created social media profiles and set about targeting club and national racers, emailing series directors to try to get in to produce the mandatory series sponsor logos for them and also contacted a few better know drivers to offer sponsorship in the form of free livery and stickers in return for on car branding.

This created results faster than I thought it would. After only a short time I'd got my company name on three cars, one in a club series one in a national beginner series and the best was the one on the side of a British Touring Car (BTCC) It had created attention to my website and social media pages and was creating a steady flow of quick turnaround work.

Being passionate about motorsport and knowing how much of a dent in a budget that a race livery can have, I had decided that the main customer base I was looking for was motorsport.

I named the company Racevinyl. Pretty simple really. I created social media profiles and set about targeting club and national racers, emailing series directors to try to get in to produce the mandatory series sponsor logos for them and also contacted a few better know drivers to offer sponsorship in the form of free livery and stickers in return for on car branding.

This created results faster than I thought it would. After only a short time I'd got my company name on three cars, one in a club series one in a national beginner series and the best was the one on the side of a British Touring Car (BTCC) It had created attention to my website and social media pages and was creating a steady flow of quick turnaround work.

I wasn't deterred with the van vinyls though, there was clearly a market for the products as I'd received a few orders for items other than basic lettering too and as I took more orders and used the machine regularly my confidence was growing.

One afternoon I received an email through eBay from a lady who ran a fork lift truck hire company in Birmingham. She needed 250 A4 sized stickers of black cut vinyl lettering with their name, email and emergency contact number on.This was my first big order and I set about quoting for the job.

It was a rush order too so I added a little to the price to reflect the extra work as well as having already adjusted my postage costs for a heavier parcel.

I cut four sample pieces to try and gauge how long the whole job would take me. It took ages! The cheap, unbranded vinyl I had bought in bulk was great for the larger jobs but with such small sized letters and numbers, the Vinyl weeded terribly and took forever. (Weeding by the way is the process of removing the excess vinyl leaving just the letters and then removing the centres of the o's a's 9's etc)

I cut three or four more samples using more pressure on the cutting blade to try to make weeding easier but it really didn't help.

The adjustments on the machine stretched as far as basic alignment and cutting pressure which was controlled in grammes and put more or less force on the computer controlled blade depending on material thickness.

In the end the entire job took two days to cut, weed and apply backing paper. It was a day late being delivered and because of this I offered a 20% discount.

The customer did come back to me for a repeat order about two months later, but the issues with her first order had encouraged me to explore better quality materials.

I'd found a number of different suppliers most of whom were some distance from me so I contacted three of them and ordered a roll of their mid range black, red and white vinyls (the three colours I had been using most of) and started to experiment with them.

The difference was immediately noticeable. The feel and finish of the Vinyl and the paper it came on were clearly better.The way the vinyls cut and the ease of weeding were also impressive and although the Vinyl was quite a bit more expensive, it would save so much time and give a more consistent and higher quality end product.

These materials were all mid range vinyls, to keep the same stock of these would cost three times as much as the basic material i'd already sourced stock of, but I decided to advertise the cheap vinyl I already had in bulk, back on eBay describing it exactly as it was and sold it (within two hours) to a guy doing the same as me with his spare room, who lived only a few miles from me.

I took it round and discovered he was using it to do large numbers for a job he had numbering up 300 recycling bins. He was very guarded about his business and the type of cutter and system he had and clearly didn't want to discuss it so I took the money and used it towards re building my stock of better quality materials.

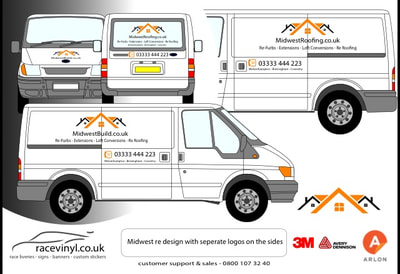

By the time the new vinyls started to arrive a day later, the eBay orders had started to pile up nicely. I was offering a set sized side panel and rear panel and customers could fill that set size with whatever text or basic logs they wanted in a range of colours at a price that increased with the complexity of the logo and number of colours used.

If a customer wanted something for a particular van I'd ask them to measure the area they wanted to cover and I would size and price the work accordingly. Everything was sent out rolled in postage tubes and I would email over a set of easy to follow installation notes. It was working well. Orders were coming in thick and fast as the eBay recommendations began to grow.

So here I was, "Racevinyl" sponsor of a BTCC team, my name in the paddock of another two race series and a stream of eBay sales for basic van vinyls. It was good, I enjoyed the work but as I'd increased my push into a more professional arena along side larger graphics companies, what I was able to do with the cutter just wasn't comparable to other companies offerings.

I took it round and discovered he was using it to do large numbers for a job he had numbering up 300 recycling bins. He was very guarded about his business and the type of cutter and system he had and clearly didn't want to discuss it so I took the money and used it towards re building my stock of better quality materials.

By the time the new vinyls started to arrive a day later, the eBay orders had started to pile up nicely. I was offering a set sized side panel and rear panel and customers could fill that set size with whatever text or basic logs they wanted in a range of colours at a price that increased with the complexity of the logo and number of colours used.

If a customer wanted something for a particular van I'd ask them to measure the area they wanted to cover and I would size and price the work accordingly. Everything was sent out rolled in postage tubes and I would email over a set of easy to follow installation notes. It was working well. Orders were coming in thick and fast as the eBay recommendations began to grow.

So here I was, "Racevinyl" sponsor of a BTCC team, my name in the paddock of another two race series and a stream of eBay sales for basic van vinyls. It was good, I enjoyed the work but as I'd increased my push into a more professional arena along side larger graphics companies, what I was able to do with the cutter just wasn't comparable to other companies offerings.

In order to remain competitive and still even be an option for some customers, I started to offer printed work, wraps and banners which I out sourced to other specialist trade printers. I would get the job, create the artwork, order from the trade supplier who would either deliver to me so I could install or deliver to my customer in blank packaging with my name on the delivery note. It got me in with some bigger customers than I'd have managed alone but it was expensive.

I did this with both motorsport and commercial customers and on the motorsport side it really squeezed my profits almost to the point where I thought, am I doing this because I love motorsport or because it makes good business sense. Being honest with myself it wasn't the latter and I knew I needed a re think.

I did this with both motorsport and commercial customers and on the motorsport side it really squeezed my profits almost to the point where I thought, am I doing this because I love motorsport or because it makes good business sense. Being honest with myself it wasn't the latter and I knew I needed a re think.

The Re-Brand

With budgets in motorsport tighter than ever, there really wasn't great profits to be made from the motorsport work. What I thought would be the main part of my businesses income wasn't going to be, I realised that now.

In the back ground though, the eBay van lettering sales were booming. I'd started to offer an installation service for customers local to me and there were excellent margins in the commercial side.

The name Racevinyl was no use to me anymore, it really didn't convey what I was doing with the commercial vehicle work and I needed something memorable, that described what I was doing and that gave a professional impression.

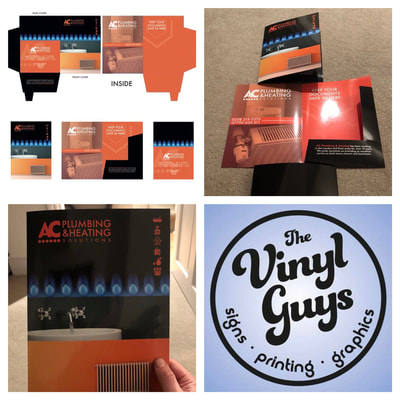

Often when I'd arrive to wrap or apply graphics to race cars, I'd go to the team manager and explain who I was, they would then shout over to one of the mechanics and say "The Vinyl guy's here show him the car" The same had been true when arriving to work on vans, I was "The guy with the van vinyls" or "The eBay vinyl guy" and so I decided that I would re brand and call the business THE VINYL GUYS.

In the back ground though, the eBay van lettering sales were booming. I'd started to offer an installation service for customers local to me and there were excellent margins in the commercial side.

The name Racevinyl was no use to me anymore, it really didn't convey what I was doing with the commercial vehicle work and I needed something memorable, that described what I was doing and that gave a professional impression.

Often when I'd arrive to wrap or apply graphics to race cars, I'd go to the team manager and explain who I was, they would then shout over to one of the mechanics and say "The Vinyl guy's here show him the car" The same had been true when arriving to work on vans, I was "The guy with the van vinyls" or "The eBay vinyl guy" and so I decided that I would re brand and call the business THE VINYL GUYS.

It worked for all sectors, there was nothing specific or confusing and it was three short words.The "s" in Guys rather than just Guy also gave a feeling of scale like there was more than just me doing everything.

I launched the new name with a new logo, website, twitter and Facebook as well as with a new (free phone) 0800 number with an answer service for when I couldn't get to the calls myself.The idea of all of this was to create the feel of a bigger company, having a person answer the phone with a script written by me and speaking to potential customers was better than just "welcome to my voicemail" the website and social media accounts allowed me to share my work and promote it to others using targeted adverts.

I had a new plan too. I now wanted to eliminate my printed vinyl out sourcing.To do this I needed to spend around £25,000 on a wide format print and cut machine, laminator, software and computer equipment as well as around £6-8,000 per year on premises because it wouldn't all fit in my spare bedroom.

My plan was the following;

- continue with the outsourcing to secure new work

- save every penny that the business made to invest back in the form of the equipment I needed

- develop my material knowledge and supplier relationships to drive down the material costs and put trade accounts in place to regulate spending

- explore the range of print and cut systems available, costs etc to price exactly what I needed.

I had by now outgrown the spare room. I was using the garage as a stock room, the dining table often became a work area and on one job I remember, a set of large panels for a pit garage wall, each one 8ft by 4ft all of which fitted side by side to create a single image, I used the kitchen and patio to lay out the job before applying it to the boards.

I'd been attending shows and visiting suppliers further a field and had secured three reliable ones with whom I'd agreed a pricing structure to give me a sliding scale of discounted materials depending on quantity purchased.

I'd also started to narrow down the machines I wanted that I thought would suit my needs.

I kept the motorsport contacts I'd made and continued to sponsor a BTCC driver and offer discounted prices to other club racers with good social media followings in exchange for some Facebook and twitter mentions and my logo on their cars.This lead to other motorsport work as well as introductions to other sponsors many of whom through their businesses ran commercial fleets.

As I shared more images and videos of work that I'd completed, I got more enquiries and orders.

By late 2015 / early '16 I'd worked on small graphics for DIY fitting, installed full wraps on cars & vans, trucks and curtain side trailers. I'd also found a really big market for banners and building signage.

Another easy and obvious upsell were leaflets and business cards. Customers having their vehicle re branded would often be interested in these to match their vehicles new look. I found a reliable supplier of these, I would do the artwork and once approved I could turn around short runs in a day.

Another easy and obvious upsell were leaflets and business cards. Customers having their vehicle re branded would often be interested in these to match their vehicles new look. I found a reliable supplier of these, I would do the artwork and once approved I could turn around short runs in a day.

Time For My Own Premises

In March 2016 I'd finally used all the space up that I could at home. Much to the delight of my wife, it was time to find some work space.

The business was regularly making enough to afford the move and it would mean increased production capacity, the ability to have a more professional workflow and if I could find the right space I was also looking for an installation area so I could have vehicles in doors to install graphics and wraps.

After a lot of searching I found a perfect office space and roller shuttered unit not far from home. It was ideally situated only a couple of miles from one of my main customers, a commercial vehicle sales and leasing specialist who was regularly putting work my way.

I set about moving my cutter, desk and computer equipment in along with the stock I had.The space totalled 950sq ft and it dwarfed my little desk and cutting set up.

I'd built this from nothing though and one thing I'd developed was a vision for how I wanted it to look. Not just the books or how I wanted the business to be seen by others but literally how I wanted the set up to look, the production "hub" how the work would flow, where everything would be stored, where I'd sit, stand, apply I could see it all. I just needed to work harder now to get there.

The space allowed me to produce and finish the bigger truck, trailer and building signage work so much faster and in a much more organised manner saving time and money. It also allowed me to do more than a couple of jobs at once too and as the orders for vehicle installations kept flowing I had started to spend even more every month in outsourced print. I NEEDED my own printer, it would be the one thing that would all of a sudden create a huge increase in profit with out any extra work or customers needed.

The business was regularly making enough to afford the move and it would mean increased production capacity, the ability to have a more professional workflow and if I could find the right space I was also looking for an installation area so I could have vehicles in doors to install graphics and wraps.

After a lot of searching I found a perfect office space and roller shuttered unit not far from home. It was ideally situated only a couple of miles from one of my main customers, a commercial vehicle sales and leasing specialist who was regularly putting work my way.

I set about moving my cutter, desk and computer equipment in along with the stock I had.The space totalled 950sq ft and it dwarfed my little desk and cutting set up.

I'd built this from nothing though and one thing I'd developed was a vision for how I wanted it to look. Not just the books or how I wanted the business to be seen by others but literally how I wanted the set up to look, the production "hub" how the work would flow, where everything would be stored, where I'd sit, stand, apply I could see it all. I just needed to work harder now to get there.

The space allowed me to produce and finish the bigger truck, trailer and building signage work so much faster and in a much more organised manner saving time and money. It also allowed me to do more than a couple of jobs at once too and as the orders for vehicle installations kept flowing I had started to spend even more every month in outsourced print. I NEEDED my own printer, it would be the one thing that would all of a sudden create a huge increase in profit with out any extra work or customers needed.

Buying My First Printer

I had my heart set on either a Roland or Mimaki print and cut system. I'd emailed and called around a number of suppliers to see if there were any ex demo deals and to see what I could get them to do on price. Apart from our house and cars this was going to be the biggest purchase I'd ever made.

I had considered lease and finance options but as the business wasn't my main job (yet) I decided that rather than commit to a monthly outgoing for a number of years I would be patient, wait and save everything the business had made to own one outright. This was only possible because we weren't relying on the income of the business to live. I hoped this would give me a little more buying power too though and enable me to be a little cheekier when putting a deal together.

I had been for demo days at a number of different suppliers to see both machines in operation. I'd by now discounted the idea of a used machine.They seemed to hold their value very well and so the difference wasn't huge and also being totally new to using these machines the main thing I wanted was the support and backup that came with the new machine as well as a long and trustworthy warranty.

I had booked to attend a trade show at the NEC in September and I believed that this would be a great place to get an amazing deal on a machine. It would be a chance to see the machines side by side and speak to the manufacturers, suppliers and also users to see what would be he best value for me.

After a lot of walking between the Roland and Mimaki stands and between two re sellers as well as talking to three very helpful business owners I'd made my decision, it was Roland for me.

Their support network, training academy and warranty were amazing. I'd had recommendations for both but the ones for Roland were more passionate.Their team were so helpful and the quality of the output and software were brilliant.

I'd also found my supplier. We had discussed ongoing material and ink pricing deals too as I was paying for the machine outright and not only that but on their stand they had a brand new machine that had done a few hours demo printing.They went and agreed with Roland that they could sell it to me as new with a full warranty. It was a done deal, I owned a printer.

We agreed delivery, installation and training for November ('16) I was so excited!

I had considered lease and finance options but as the business wasn't my main job (yet) I decided that rather than commit to a monthly outgoing for a number of years I would be patient, wait and save everything the business had made to own one outright. This was only possible because we weren't relying on the income of the business to live. I hoped this would give me a little more buying power too though and enable me to be a little cheekier when putting a deal together.

I had been for demo days at a number of different suppliers to see both machines in operation. I'd by now discounted the idea of a used machine.They seemed to hold their value very well and so the difference wasn't huge and also being totally new to using these machines the main thing I wanted was the support and backup that came with the new machine as well as a long and trustworthy warranty.

I had booked to attend a trade show at the NEC in September and I believed that this would be a great place to get an amazing deal on a machine. It would be a chance to see the machines side by side and speak to the manufacturers, suppliers and also users to see what would be he best value for me.

After a lot of walking between the Roland and Mimaki stands and between two re sellers as well as talking to three very helpful business owners I'd made my decision, it was Roland for me.

Their support network, training academy and warranty were amazing. I'd had recommendations for both but the ones for Roland were more passionate.Their team were so helpful and the quality of the output and software were brilliant.

I'd also found my supplier. We had discussed ongoing material and ink pricing deals too as I was paying for the machine outright and not only that but on their stand they had a brand new machine that had done a few hours demo printing.They went and agreed with Roland that they could sell it to me as new with a full warranty. It was a done deal, I owned a printer.

We agreed delivery, installation and training for November ('16) I was so excited!

I spent the rest of the show listening to the suppliers material advice and also speaking to Roland's recommended material supplier about their range and pricing. By now I'd developed a good knowledge of materials and what I'd use most of.

I no longer traded on eBay and I'd ventured far from the budget end of the materials range.

I had positioned the business as selling not only a product but a full service.

I would meet with customers in person, when possible, and discuss their needs. I could show them the materials and talk about the differences between the cheaper, mid range and top end vinyls and wraps and with them, decide which best suited their project.

I'd do the same with the design process. I wouldn't say to them, for this price you can have this many re designs or this is the design for this much and this one for this much, it would be more of a process than that. This, more personal service meant that I wasn't just giving a price and a final product, I was giving advice, listening to a customers needs and explaining my prices and this had lead to an overall increase in the average customer spend. I was providing a solution.

By the time the printer arrived I was more than ready for it.The week before it was delivered I'd spent almost £1000 in outsourced vinyl printing. With the machine this would have cost me around £200 (max) in ink, material & time so you can see the immediate profit increase that the machine would generate.

I no longer traded on eBay and I'd ventured far from the budget end of the materials range.

I had positioned the business as selling not only a product but a full service.

I would meet with customers in person, when possible, and discuss their needs. I could show them the materials and talk about the differences between the cheaper, mid range and top end vinyls and wraps and with them, decide which best suited their project.

I'd do the same with the design process. I wouldn't say to them, for this price you can have this many re designs or this is the design for this much and this one for this much, it would be more of a process than that. This, more personal service meant that I wasn't just giving a price and a final product, I was giving advice, listening to a customers needs and explaining my prices and this had lead to an overall increase in the average customer spend. I was providing a solution.

By the time the printer arrived I was more than ready for it.The week before it was delivered I'd spent almost £1000 in outsourced vinyl printing. With the machine this would have cost me around £200 (max) in ink, material & time so you can see the immediate profit increase that the machine would generate.

The day was filled with training and me making notes in the hope that I could get straight to work with it. I'd got jobs waiting and although I still had the trusty old cutter, this machine would replace that as it would print and cut or just cut depending on the work. It was also over double the width so I could buy wider materials which were cheaper than the 600mm vinyls so there would be a slight material saving too.

I got to grips with the software straight away. I'd bought a new stand alone computer to run the printer and RIP software as well as invested in a new MacBook Pro and iMac both linked to my Adobe suite software package subscription. I worked between the MacBook at home and the iMac in the office both being updated using the OneDrive cloud as well as Adobes own cloud service.

To design and offer proof work for vehicle graphics I had also invested in an amazing product by Impact Graphics. A set of 1:20 scale vehicle outlines, cars, vans, trucks, busses, bin lorries you name it, they have it. This meant I could design the wrap or graphics on the outline, send it as a visual to a customer for approval and once approved, send the design through the rip software (at 2000%) making it full sized (without having to get a customer to measure a thing) and hit print. The accuracy of these drawings is spot on, if you have anything to do with vehicle graphic design it's an essential investment.

So by the end of 2016 the printer was in and I'd got to grips with it but all work for long term vehicle installations needed to be laminated.This would give the 3,5,7 or 12 year life span guaranteed depending on the material and laminate used. I now needed a laminator.

In the same way as I'd searched for my printer I'd been looking at Laminators, who made the best and where I could get the best deals. Now this is one I promised not to talk about in detail as the deal was very good (mainly because I was able to once again buy the machine outright) but the guys at Vivid did me an awesome deal on a brand new machine.

I got to grips with the software straight away. I'd bought a new stand alone computer to run the printer and RIP software as well as invested in a new MacBook Pro and iMac both linked to my Adobe suite software package subscription. I worked between the MacBook at home and the iMac in the office both being updated using the OneDrive cloud as well as Adobes own cloud service.

To design and offer proof work for vehicle graphics I had also invested in an amazing product by Impact Graphics. A set of 1:20 scale vehicle outlines, cars, vans, trucks, busses, bin lorries you name it, they have it. This meant I could design the wrap or graphics on the outline, send it as a visual to a customer for approval and once approved, send the design through the rip software (at 2000%) making it full sized (without having to get a customer to measure a thing) and hit print. The accuracy of these drawings is spot on, if you have anything to do with vehicle graphic design it's an essential investment.

So by the end of 2016 the printer was in and I'd got to grips with it but all work for long term vehicle installations needed to be laminated.This would give the 3,5,7 or 12 year life span guaranteed depending on the material and laminate used. I now needed a laminator.

In the same way as I'd searched for my printer I'd been looking at Laminators, who made the best and where I could get the best deals. Now this is one I promised not to talk about in detail as the deal was very good (mainly because I was able to once again buy the machine outright) but the guys at Vivid did me an awesome deal on a brand new machine.

Sadly and unexpectedly my Dad died on 6th January 2017. So the laminator delivery didn't happen until February 2017.

My dad was a huge inspiration to me in growing my business. He and his business partner had done the same with their company in the 90's making a huge success from nothing and he'd gone on to do the same in a number of other business ventures so he'd always been a sounding board for my ideas and plans.

Just over a month later in late February 2017 I lost another huge influence in my adult life, when my father in law died. As you can imagine the start of 2017 was indescribably hard for my wife and I as well as a hugely distressing and confusing time for my young daughter.

My father in law was responsible for my patience in business, he had taken an immense interest in the business and was genuinely amazed at the results I was getting. He would ask a lot of questions and when I answered he would always have another angle for me to consider. He was the one who made me realise it was best to wait, push sales, earn more and buy outright avoiding owing money on the companies main equipment.

Along with my wife and my Dad, he was one of the people who delighted in seeing and hearing about what I was doing and gave great advice.

It's here that I will reiterate the huge importance of building relationships with clients as well as other business owners in your sector.

Whilst I was away from my main job and my print business for the first three months of 2017 to be with my family, I was able to contact my most regular customers and explain what had happened.

I understood that their businesses still required print work and so I was able to put them in touch with two friends I'd made through the business, who also ran print companies in the area and suggest that they put the regular work I'd been doing for them, through these other printers.

I knew that my customers would be happy with their work and I was offering a seamless solution to their print work issue created by my situation. My printer friends were happy with the extra work (I sent them the artwork making it easy) and my customers were understanding because I'd built that relationship with them.

I'm happy to say that the customers came straight back to me when I started back up and It built a stronger friendship with the other printers (for one of whom I now do regular overspill work)

Growing The Business

Life goes on as we all know though, as does business and so by Late March I was back to it. I was really pushing the social media side of things and engaging with as many different sectors as possible.

I reached out to a few other people I could see were starting out the same way I had and offered them the chance to come to my office and have a coffee, a chat and a look round to see what I do and how I do it.

I had two of them take me up on the offer and I really enjoyed talking about the details of my business and how I'd used a range of free and paid training across a range of media to learn how to grow and what to offer customers.

I found that there were three main things people wanted to know about and they were pricing, materials and how to find customers.

With one couple who came to see me I ended up spending most of the day with them.They're In a slightly different market to me but their business has grown as has their confidence and social media reach and I like to think I had a little something to do with that :)

I found that my little 600mm cutter was being left in the corner unused and it had been an amazing little machine that could still be the key to someone else starting another great business. I decided to sell it and advertise it as just that, a business starter package.

I used the free Facebook marketplace app to sell the cutter and computer, a load of additional software I'd collected and used over the time I had it as my main machine including some of the vehicle outline software and a few boxes of vinyl, tools and the offer of free training to go with it all.

I advertised the whole package for £1000 and it quickly sold too.The buyer came to have a look at everything, I suggested she come and see what it can do and then if it's what she wanted she could buy and if not then I'd keep the advert live.

She came for the morning and I showed her it all working and we designed and cut a few examples. She already had a thriving paper and card print business but wanted to expand into vehicles and signage. She had travelled a couple of hours to get to me so it suited the business that she wasn't on my doorstep and we agreed that I'd deliver everything to her and help install and integrate it into their current print room. It was another useable cash injection back into the business and after having installed it,

over 5 months later I was asked to go back for another training day to refresh her and another new member of staff, which I did and was paid well for.

Up until now I had been delivering a few local orders and when I was going to install work or collect large material orders I was using the family hatchback. My business had outgrown the family home and now the family car too. I set about looking at vans. My initial idea was to look for something a few years old and use it as and when I needed it and just leave it Parked up in the unit the rest of the time.

After talking it through with my wife, she had made me realise it was a bit of a waste for me to run a vehicle that would mainly be sitting parked up.

Her car was due a change probably in a year or so and so we decided we would sell her car earlier than planned, she would have mine and I would find a nearly new van and use it as a daily driver. It was a sensible plan. We found a 2016 swb Vivaro van in a metallic grey with under 8k miles on it and a great trim and spec so I would be comfy using it daily.

It was a great purchase, saved me loads on materials delivery charges (as I could now collect more from local suppliers) and it was a more professional look when I turned up at jobs.

Late 2017 really saw another huge rise in social media interest, quotes and orders. I started to produce a range of custom service reminder labels, warning stickers and other products for the heating, electrical and plumbing sector.

Those guys love Twitter. It's an awesome sector, they help each other out, share tips and advice as well as jobs they've done and they all seem to support each other well and champion each others work.

I was able to get a few orders from local guys and in turn their pictures and comments on the work I've done for them lead to orders from further a field.

In November I produced over 8,000 labels in total and all from a couple of Twitter engagements and posts that probably took me a couple of hours.

I have also tried to promote the business locally through things more interesting than simple paid adverts.

I bought the kits for an under 9s football team who were struggling to find a main sponsor. I paid for an advert in the programme of a local children's theatre companys recent production and I've undertaken more obvious promotions like free giveaways of "No Tools Left In This Van Overnight" stickers, which were very popular.

A promotion like that also gave me details of hundreds of small business owners with vans, really useful marketing info.

I have also just offered a huge run of free service reminder labels to a trade magazine in the plumbing and heating sector.This will create value for them, as they offer them to their readers for free, and value for me as it again gives me details of engineers interested in a product I make.

These are all longer term promotions, I may not see the financial benefit for a few weeks or even months and with the football strips I may not see a quantifiable return at all but it got the name, the logo and my willingness to put back into my community out there.

Although having written that last paragraph, it turns out that one of my most recent jobs which was a total re brand of a companies logo, their van, business cards and leaflets came through the football team sponsorship. My customers son plays for the team which encouraged him to find my social media pages. He decided to get in touch for a quote and was happy to go ahead.You never know where the next job will come from sometimes but you have to be out there, constantly promoting in a range of different ways to give yourself the best chance of attracting new clients.

I reached out to a few other people I could see were starting out the same way I had and offered them the chance to come to my office and have a coffee, a chat and a look round to see what I do and how I do it.

I had two of them take me up on the offer and I really enjoyed talking about the details of my business and how I'd used a range of free and paid training across a range of media to learn how to grow and what to offer customers.

I found that there were three main things people wanted to know about and they were pricing, materials and how to find customers.

With one couple who came to see me I ended up spending most of the day with them.They're In a slightly different market to me but their business has grown as has their confidence and social media reach and I like to think I had a little something to do with that :)

I found that my little 600mm cutter was being left in the corner unused and it had been an amazing little machine that could still be the key to someone else starting another great business. I decided to sell it and advertise it as just that, a business starter package.

I used the free Facebook marketplace app to sell the cutter and computer, a load of additional software I'd collected and used over the time I had it as my main machine including some of the vehicle outline software and a few boxes of vinyl, tools and the offer of free training to go with it all.

I advertised the whole package for £1000 and it quickly sold too.The buyer came to have a look at everything, I suggested she come and see what it can do and then if it's what she wanted she could buy and if not then I'd keep the advert live.

She came for the morning and I showed her it all working and we designed and cut a few examples. She already had a thriving paper and card print business but wanted to expand into vehicles and signage. She had travelled a couple of hours to get to me so it suited the business that she wasn't on my doorstep and we agreed that I'd deliver everything to her and help install and integrate it into their current print room. It was another useable cash injection back into the business and after having installed it,

over 5 months later I was asked to go back for another training day to refresh her and another new member of staff, which I did and was paid well for.

Up until now I had been delivering a few local orders and when I was going to install work or collect large material orders I was using the family hatchback. My business had outgrown the family home and now the family car too. I set about looking at vans. My initial idea was to look for something a few years old and use it as and when I needed it and just leave it Parked up in the unit the rest of the time.

After talking it through with my wife, she had made me realise it was a bit of a waste for me to run a vehicle that would mainly be sitting parked up.

Her car was due a change probably in a year or so and so we decided we would sell her car earlier than planned, she would have mine and I would find a nearly new van and use it as a daily driver. It was a sensible plan. We found a 2016 swb Vivaro van in a metallic grey with under 8k miles on it and a great trim and spec so I would be comfy using it daily.

It was a great purchase, saved me loads on materials delivery charges (as I could now collect more from local suppliers) and it was a more professional look when I turned up at jobs.

Late 2017 really saw another huge rise in social media interest, quotes and orders. I started to produce a range of custom service reminder labels, warning stickers and other products for the heating, electrical and plumbing sector.

Those guys love Twitter. It's an awesome sector, they help each other out, share tips and advice as well as jobs they've done and they all seem to support each other well and champion each others work.

I was able to get a few orders from local guys and in turn their pictures and comments on the work I've done for them lead to orders from further a field.

In November I produced over 8,000 labels in total and all from a couple of Twitter engagements and posts that probably took me a couple of hours.

I have also tried to promote the business locally through things more interesting than simple paid adverts.

I bought the kits for an under 9s football team who were struggling to find a main sponsor. I paid for an advert in the programme of a local children's theatre companys recent production and I've undertaken more obvious promotions like free giveaways of "No Tools Left In This Van Overnight" stickers, which were very popular.

A promotion like that also gave me details of hundreds of small business owners with vans, really useful marketing info.

I have also just offered a huge run of free service reminder labels to a trade magazine in the plumbing and heating sector.This will create value for them, as they offer them to their readers for free, and value for me as it again gives me details of engineers interested in a product I make.

These are all longer term promotions, I may not see the financial benefit for a few weeks or even months and with the football strips I may not see a quantifiable return at all but it got the name, the logo and my willingness to put back into my community out there.

Although having written that last paragraph, it turns out that one of my most recent jobs which was a total re brand of a companies logo, their van, business cards and leaflets came through the football team sponsorship. My customers son plays for the team which encouraged him to find my social media pages. He decided to get in touch for a quote and was happy to go ahead.You never know where the next job will come from sometimes but you have to be out there, constantly promoting in a range of different ways to give yourself the best chance of attracting new clients.

Time For More Hard Work

It's a theme that should run through every aspect of your business.

Want more customers? Work harder for them. Want new equipment? Work harder for it.

Want to grow your income? Work harder.

It's the main piece of advice you need really, work hard until you're bleeding out of your eyes.

Sorry, I've stolen that last line from one of the best entrepreneurs I've listened to, watched and followed for the last two years Gary Vaynerchuk.

He's been a huge influence to me. He made me realised I needed to push so hard and do so much and is an amazing business man to follow.

Search for him on YouTube, podcasts and all social media platforms, give his stuff a watch and give it 4-6 episodes to really get a flavour of what he's about. It will be worth it!

Garys mentality, work ethic and his huge library of audio, video and written work are what has pushed me to be where I am now. On the off chance he reads the copy of this I'll be sending him, I'd like to just say Thank You Gary! I know you don't do it to get stuff in return but I owe you big time so if there's anything I can ever do for you, you got it!

Want more customers? Work harder for them. Want new equipment? Work harder for it.

Want to grow your income? Work harder.

It's the main piece of advice you need really, work hard until you're bleeding out of your eyes.

Sorry, I've stolen that last line from one of the best entrepreneurs I've listened to, watched and followed for the last two years Gary Vaynerchuk.

He's been a huge influence to me. He made me realised I needed to push so hard and do so much and is an amazing business man to follow.

Search for him on YouTube, podcasts and all social media platforms, give his stuff a watch and give it 4-6 episodes to really get a flavour of what he's about. It will be worth it!

Garys mentality, work ethic and his huge library of audio, video and written work are what has pushed me to be where I am now. On the off chance he reads the copy of this I'll be sending him, I'd like to just say Thank You Gary! I know you don't do it to get stuff in return but I owe you big time so if there's anything I can ever do for you, you got it!

Spending hours on social media may seem like a waste of time to you. It may not pay off for a month or 6 months or 2 years but it's essential.You need a social media prescience because that's where your customers are.They are there when they're on a break at work or during the tv adverts or when they're bored, you can find and reach the customers you want easily and cheaply.

I don't want to seem like I'm just saying what Gary says in his videos and audio so I'll just slip in another reminder here to go watch and listen to his stuff, he's the king of social media and will tell you what to do.

I will speak of my experiences though and about what I've done to grow my following. I try to update my social accounts daily sometimes once or twice and some days 6 or 8 depending on what's going on. Some times I do daytime updates and sometimes evenings.The results vary and I've gotten to know when for me, is the best time to post, what my followers like to see and the rest of the time I spend engaging.

I follow the pages and profiles of other printers, sign makers and wrappers, and they follow me. If I see work I like, I share it and I tell them that I like it and ask about their processes and materials.

I think some people consider it risky doing this because it means a lot of the time my own customers get to see me sharing other companies work but I'm not worried.

I am confident in my work, in the service and materials that I offer and it's easy for my customers to look for other companies on their own using a whole host of platforms if they wanted to, which is why I build the relationships and offer the service that I do, that's what sets me apart from the competition.

I don't want to seem like I'm just saying what Gary says in his videos and audio so I'll just slip in another reminder here to go watch and listen to his stuff, he's the king of social media and will tell you what to do.

I will speak of my experiences though and about what I've done to grow my following. I try to update my social accounts daily sometimes once or twice and some days 6 or 8 depending on what's going on. Some times I do daytime updates and sometimes evenings.The results vary and I've gotten to know when for me, is the best time to post, what my followers like to see and the rest of the time I spend engaging.

I follow the pages and profiles of other printers, sign makers and wrappers, and they follow me. If I see work I like, I share it and I tell them that I like it and ask about their processes and materials.

I think some people consider it risky doing this because it means a lot of the time my own customers get to see me sharing other companies work but I'm not worried.

I am confident in my work, in the service and materials that I offer and it's easy for my customers to look for other companies on their own using a whole host of platforms if they wanted to, which is why I build the relationships and offer the service that I do, that's what sets me apart from the competition.

I run competitions and simple give always to grow my followers from particular sectors and to grow my email and social contact list.

As I write this I'm at the airport in Cuba waiting for my flight home after a much needed family holiday. (Yes I've been working the odd hour per day when I've been away - it's hard not too) I try to fit work in when I can :-)

On my return I have plans to giveaway a product from a company that make custom van racking. It's a great product and something that I use daily and one of their most popular sellers so it's going to be our biggest and most entered comp yet I'm sure of it!

I met the company that supply it through twitter and have done a little bit of promoting for them, as have they for me.

I have also helped them out with some scale drawings they needed (for free) and so when it came to thinking about what to give away, they were the first people I thought of.

They returned my favour by letting me buy the item I'm giving away at cost price. I will promote them through the giveaway and they will promote my giveaway so both of us will most likely gain relevant and interested followers.

At the end of the giveaway I will also have a list of people (and their social media profile details) who are interested in the product.

That list will have value to the company supplying it, so who knows maybe I'll use that to see if they'd want to do a similar giveaway with one of my products or services.

I said it earlier, but again, this is another example of one of the most valuable things I've done in business.....Build relationships with other business owners! Never under estimate that or be too insular when it comes to your business, be proud and share you're story, you'll be surprised how many people are genuinely interested.

I love being asked questions about my business and my set up. I'm enthusiastic about the whole process and I like to think that it shows and has an effect on people who are asking because they want to, or have already set up a similar business.

There are so many things I could discuss, particulars of jobs, installations, sales strategies or pricing and many more but I'd rather wait and see what people want to know.

Hopefully this is the start of another interesting journey in my business life......I'd like to invite anyone out there to ask any questions, arrange to come and check out my set up, email, call or message with questions or problems, get in touch for more specific advice or for contacts in the materials, hardware or software space or anything else I can help with.

As I write this I'm at the airport in Cuba waiting for my flight home after a much needed family holiday. (Yes I've been working the odd hour per day when I've been away - it's hard not too) I try to fit work in when I can :-)

On my return I have plans to giveaway a product from a company that make custom van racking. It's a great product and something that I use daily and one of their most popular sellers so it's going to be our biggest and most entered comp yet I'm sure of it!

I met the company that supply it through twitter and have done a little bit of promoting for them, as have they for me.

I have also helped them out with some scale drawings they needed (for free) and so when it came to thinking about what to give away, they were the first people I thought of.

They returned my favour by letting me buy the item I'm giving away at cost price. I will promote them through the giveaway and they will promote my giveaway so both of us will most likely gain relevant and interested followers.

At the end of the giveaway I will also have a list of people (and their social media profile details) who are interested in the product.

That list will have value to the company supplying it, so who knows maybe I'll use that to see if they'd want to do a similar giveaway with one of my products or services.

I said it earlier, but again, this is another example of one of the most valuable things I've done in business.....Build relationships with other business owners! Never under estimate that or be too insular when it comes to your business, be proud and share you're story, you'll be surprised how many people are genuinely interested.

I love being asked questions about my business and my set up. I'm enthusiastic about the whole process and I like to think that it shows and has an effect on people who are asking because they want to, or have already set up a similar business.

There are so many things I could discuss, particulars of jobs, installations, sales strategies or pricing and many more but I'd rather wait and see what people want to know.

Hopefully this is the start of another interesting journey in my business life......I'd like to invite anyone out there to ask any questions, arrange to come and check out my set up, email, call or message with questions or problems, get in touch for more specific advice or for contacts in the materials, hardware or software space or anything else I can help with.

Future Plans

As I mentioned earlier I am currently looking for new premises. I'm aiming for somewhere in a similar area we are now, around 1500sq ft with a larger workspace and installation unit and a more long term lease. Where I am at the moment was meant to be longer term but the landlord has decided to sell up leaving me until

June / July to find a new place, not ideal but I've turned it into a positive and will be making new space for clothing personalisation and UV printing.

That leads me nicely to my plans for the future of the business. Firstly I'll be investing in clothing personalisation.Tee shirts, hoodies and a range of custom apparel, another string to the Roland's bow that I'm currently not playing and should be.

I'm currently looking through the range of machines on offer and as usual hunting for the best prices. I'm also looking to invest in a UV printing capability, the scope of work that's possible is incredible and it's certainly going to open up a number of new revenue streams.

As I write this section, I'm now on my flight, 5 and a bit hours from landing at Manchester airport at 37,048feet travelling at 695mph. When I get back I've got another trade show to look forward to in a fortnight at the NEC.

I'm going for a few reasons this year, catching up with the suppliers I've not had chance to see the last 12 months and only speak to on the phone, meet new people doing what I do and to look at heat press, direct to garment and UV print technology and see if I can be cheeky with some show deals again.

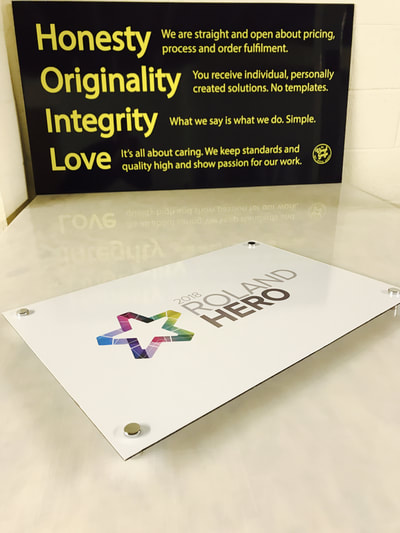

I am also there as an exhibitor on the Roland stand. Thanks to all my social media engagement and sharing images and stories of my projects and my business, I've been invited on the stand as a Roland user to talk to other customers and potential customers about how I've built my business and how my business has been changed by the purchase of my machine. As you can now see, I've got a lot to say about that. I've also been awarded the status of "Roland Hero" by the company. This is amazing and I'm so excited to be able to share my journey with even more of their potential customers and tell them how my Roland has really transformed my business.

As well as hardware purchases and new product lines, I also see me taking on one or two new members of the team. I have one trainee installer and general helper at the moment working on an "as-and-when" sort of basis and I also sub contract some design work to a graphic designer who I met through my customer network. He's an experienced and very well sought after designer and I'm lucky to have been introduced to him.

This is all leading to my exit from my full time career (of 16 years) and the move into the print industry full time.

My plan has always been to ensure the continuity of my earnings and reduce the risk to my family when I did make the move, which is another motivation behind me as I look ahead 8-12 months.

So that's it! You're up to date now and you know where I'm aiming the business and why. Before I end though just a reminder......I'd like to invite anyone out there to ask any questions, arrange to come and check out my set up, email, call or message with questions or problems, get in touch for more specific advice or for contacts in the materials, hardware or software space or anything else I can help with.

Hopefully you've enjoyed reading. Feel free to throw me some feedback, good or bad, I'm keen to improve and make this sort of thing a regular part of my social media feeds and try to give something back to the industry and help to inspire and educate.

Speak soon,

Alex

Email: [email protected]

Web: www.TheVinylGuys.co.uk

Twitter: @TheVinylGuys

Facebook: Thevinylguys.co.uk

Insta:The Vinyl Guys

LinkedIn: Alex Liggett (Wolverhampton)

Tel: 0800 107 3240

We are based in the West Midlands, DY5 1RG (get in touch to arrange a visit) we always have the kettle on standby and usually a packet biscuits on the go :)

I'm more than happy to demonstrate any of our amazing software or hardware and give a first hand look, to anyone who's interested, at the huge range of products that can be produced.

June / July to find a new place, not ideal but I've turned it into a positive and will be making new space for clothing personalisation and UV printing.

That leads me nicely to my plans for the future of the business. Firstly I'll be investing in clothing personalisation.Tee shirts, hoodies and a range of custom apparel, another string to the Roland's bow that I'm currently not playing and should be.

I'm currently looking through the range of machines on offer and as usual hunting for the best prices. I'm also looking to invest in a UV printing capability, the scope of work that's possible is incredible and it's certainly going to open up a number of new revenue streams.

As I write this section, I'm now on my flight, 5 and a bit hours from landing at Manchester airport at 37,048feet travelling at 695mph. When I get back I've got another trade show to look forward to in a fortnight at the NEC.

I'm going for a few reasons this year, catching up with the suppliers I've not had chance to see the last 12 months and only speak to on the phone, meet new people doing what I do and to look at heat press, direct to garment and UV print technology and see if I can be cheeky with some show deals again.

I am also there as an exhibitor on the Roland stand. Thanks to all my social media engagement and sharing images and stories of my projects and my business, I've been invited on the stand as a Roland user to talk to other customers and potential customers about how I've built my business and how my business has been changed by the purchase of my machine. As you can now see, I've got a lot to say about that. I've also been awarded the status of "Roland Hero" by the company. This is amazing and I'm so excited to be able to share my journey with even more of their potential customers and tell them how my Roland has really transformed my business.

As well as hardware purchases and new product lines, I also see me taking on one or two new members of the team. I have one trainee installer and general helper at the moment working on an "as-and-when" sort of basis and I also sub contract some design work to a graphic designer who I met through my customer network. He's an experienced and very well sought after designer and I'm lucky to have been introduced to him.

This is all leading to my exit from my full time career (of 16 years) and the move into the print industry full time.

My plan has always been to ensure the continuity of my earnings and reduce the risk to my family when I did make the move, which is another motivation behind me as I look ahead 8-12 months.

So that's it! You're up to date now and you know where I'm aiming the business and why. Before I end though just a reminder......I'd like to invite anyone out there to ask any questions, arrange to come and check out my set up, email, call or message with questions or problems, get in touch for more specific advice or for contacts in the materials, hardware or software space or anything else I can help with.

Hopefully you've enjoyed reading. Feel free to throw me some feedback, good or bad, I'm keen to improve and make this sort of thing a regular part of my social media feeds and try to give something back to the industry and help to inspire and educate.

Speak soon,

Alex

Email: [email protected]

Web: www.TheVinylGuys.co.uk

Twitter: @TheVinylGuys

Facebook: Thevinylguys.co.uk

Insta:The Vinyl Guys

LinkedIn: Alex Liggett (Wolverhampton)

Tel: 0800 107 3240

We are based in the West Midlands, DY5 1RG (get in touch to arrange a visit) we always have the kettle on standby and usually a packet biscuits on the go :)

I'm more than happy to demonstrate any of our amazing software or hardware and give a first hand look, to anyone who's interested, at the huge range of products that can be produced.